Ultrahigh molecular weight polyethylene (UHMWPE), has been used as a bearing material for an acetabular prosthesis component in hip and knee total joint replacement due to its unique characteristics. However, this artificial joint would be destroyed by the polyethylene wear debris fragments generated in the actual application process during long term use.

The research group headed by Professor YAN Xingbinat the State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics (LICP), Chinese Academy of Sciences (CAS), used nanometer particle reinforced materials technology to improve the friction and wear performance of the UHMWPE. By employing the graphene with high strength, high modulus, high hardness and low friction coefficient, the properties of the UHMWPE have been enhanced remarkably. This is mainly due to the forming of the transfer film of UHMWPE as graphene oxide (GO) content increases.

Hopefully, the work would be of guiding significance for the development of artificial joint materials.

The work has received support from the National Natural Science Foundation of China (No. 51005225) and Hundred Talents Program of the Chinese Academy of Sciences. The findings have been published in Tribol Lett.

Tribol Lett Paper

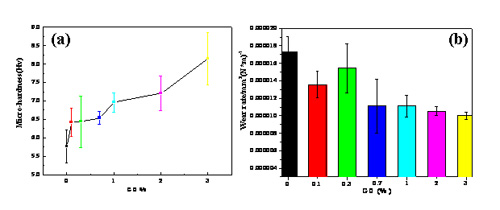

The microhardness and wear rate of GO/UHMWPE composites with the different GO contents. (Image by YAN Xingbin et al.)

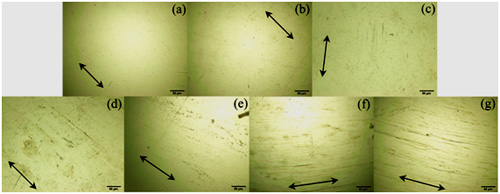

Optical images of ZrO2 balls after cleaning against GO/UHMWPE with different GO content, respectively. (a): 0 wt%, (b): 0.1%, (c): 0.3 wt%, (d): 0.7wt%, (e): 1wt%, (f): 2wt% and (g): 3wt%. The arrows indicate the sliding direction.(Image by YAN Xingbin et al.)