Ordered mesoporous materials have received much attention due to their high specific area, tuned pore size and high pore volume and potential application in many fields, such as catalysis, gas separation, gas sensing and electrochemical energy storage.

The research group of tribology of low-dimensional materials at the State Key Laboratory of Solid Lubrication of the Lanzhou Institute of Chemical Physics, CAS, has prepared high ordered cubic mesoporous CMK-8 sing mesoporous SBA-15 as template via nanocasting strategy which can be used as the active materials for supercapacitors.

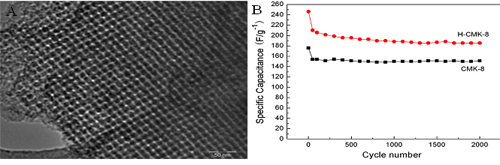

Electrochemical test suggests that the electrode prepared from CMK-8 shows specific capacitance of 176F/gat a current density of 0.625A/g in 2M KOH electrolyte. After acid treatment, the specific capacitance can be further increased to 247F/g. After 2000 cycling, the specific capacitance of acid treatment CMK-8 is still up to 185F/g, which suggests that the acid treatment CMK-8 is an excellent electrode material for supercapacitors. These encouraging results demonstrate the exciting potential of high performance supercapacitors based on such ordered 3D mesoporous carbon materials. The findings have been published in Journal of Power Source (196, 2011, 10472-10478).

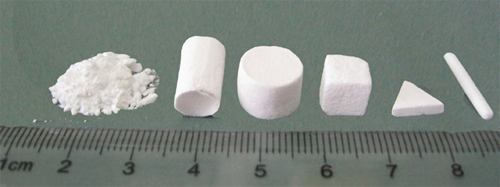

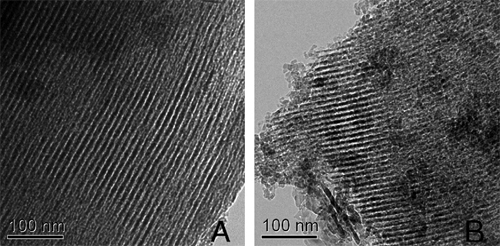

In addition, researchers have also fabricated mesoporous SiOC, SiC and Al2O3 monoliths using CMK-8 and SBA-15 as template via nanocasting strategy, respectively. These materials displays high surface areas, high pore volumes and narrow pore size combined with good mechanical property, which endow them with potential application in high catalyst support. The findings have been published in Microporous and Mesoporous Materials(135, 2010, 137-142; 138, 2011, 40-44; 142, 2011, 754–758; 147, 2012, 252-258).

The work has received support from the National Natural Science Foundation of China, National Program on Key Basic Research Project of China (973 Program), Hundred Talents Program of the CAS and the Postdoctoral Science Foundation of China (20100480728).

Photograph of ordered mesoporous alumina powders and monoliths with various shapes. (Image by YAN Xingbin et al.)

TEM images of the ordered mesoporous Al2O3 monoliths prepared at different temperatures: (A) 700 ℃and (B) 1000 ℃. (Image by YAN Xingbin et al.)

(A) TEM images of the CMK-8 taken along the [5 3 1] direction,(B) cycle life of the CMK-8 and CMK-8 after acid treatment electrodes at the current densities of 1.25 A/g. (Image by YAN Xingbin et al.)

Journal of Power Sources (196, 2011, 10472-10478)

Microporous and Mesoporous Materials (135, 2010, 137-142)

Microporous and Mesoporous Materials (138, 2011, 40-44)

Microporous and Mesoporous Materials (142, 2011, 754–758)

Microporous and Mesoporous Materials (147, 2012, 252-258)